5-Axis CNC Machining (Mastercam)

Aafreen KaurProject Overview

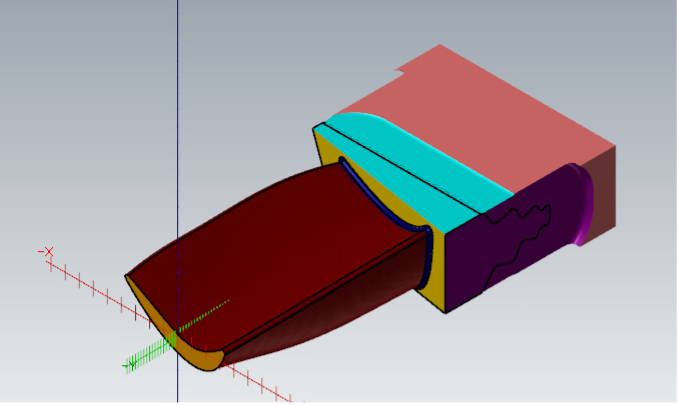

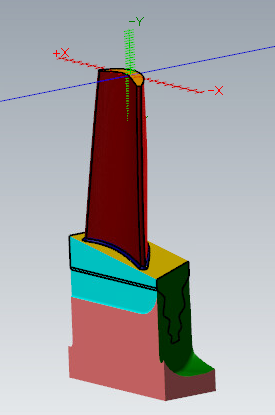

This project involves the 5-axis CNC machining of a part, modeled and programmed using Mastercam. The process utilizes an optimized machining strategy to efficiently remove stock material while maintaining surface integrity and precision.

Machining Operations Used:

- Area Roughing: Performed initial material removal using high-feed strategies to create the basic shape from the stock model.

- Morph Machining: Generated smooth toolpaths that transitioned seamlessly across the curved surfaces for optimal surface finish.

- Swarf Machining: Utilized side cutting of the tool to precisely machine inclined and complex surfaces with high accuracy.

- Parallel Machining: Applied for uniform surface finishing, ensuring even material removal and a consistent finish across the blade profile.

Tooling and Setup:

Specialized 5-axis CNC tools were selected based on surface requirements, including:

- Ball-end mills for smooth finishing of freeform surfaces.

- Tapered tools for precise cutting along the edges and intricate areas.

- High-speed cutters for efficient stock removal during roughing.