Drone Assembly - SolidWorks Design

Aafreen KaurProject Overview

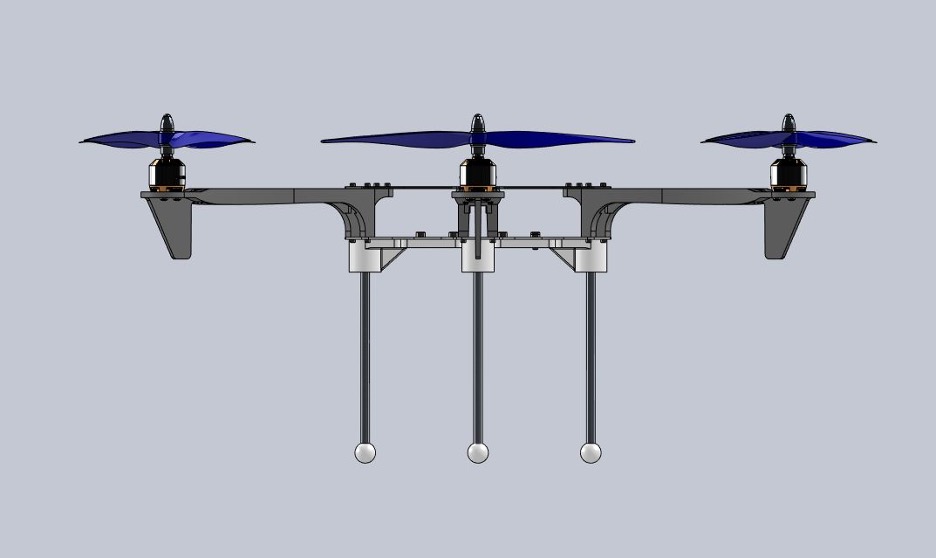

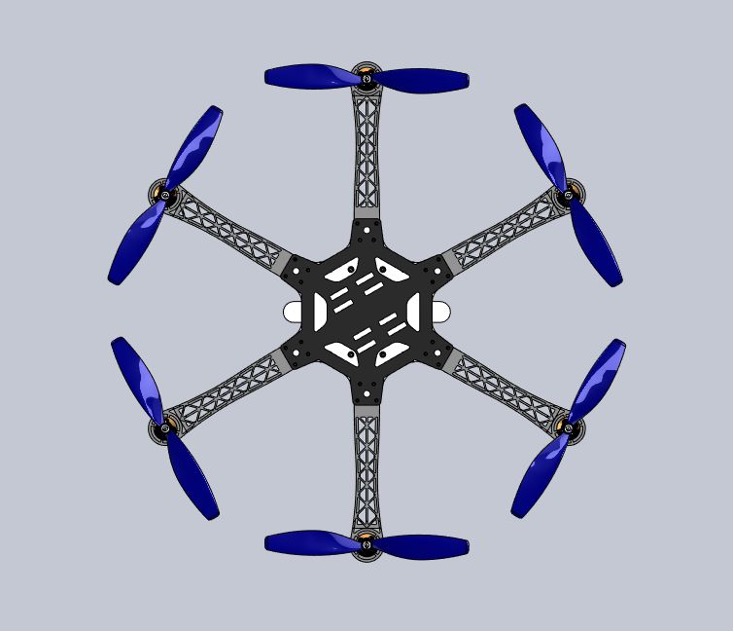

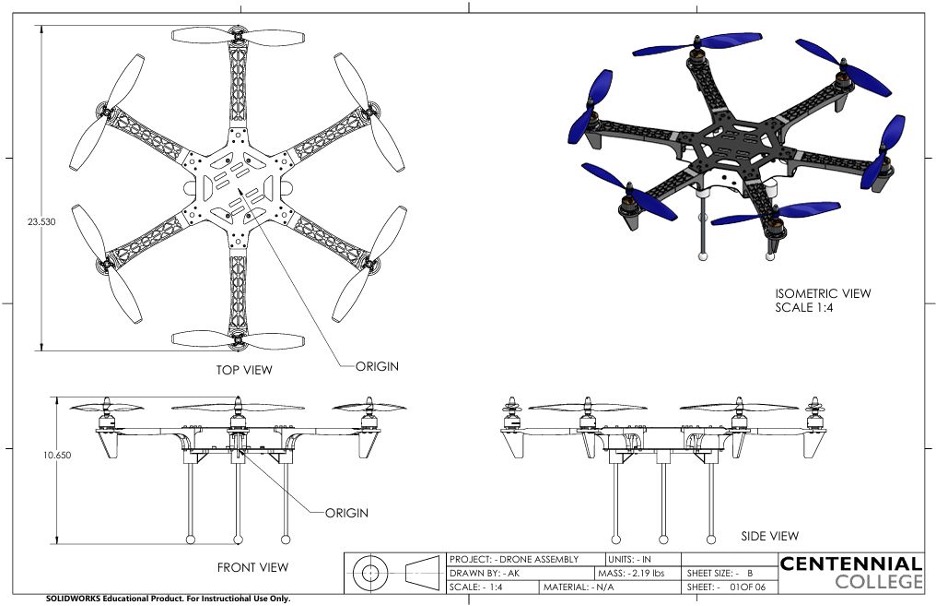

This project involves designing a modular drone system using SolidWorks, aimed to create a robust and efficient design process, modular assembly, and comprehensive documentation.

Design Components

The design includes two sub-assemblies:

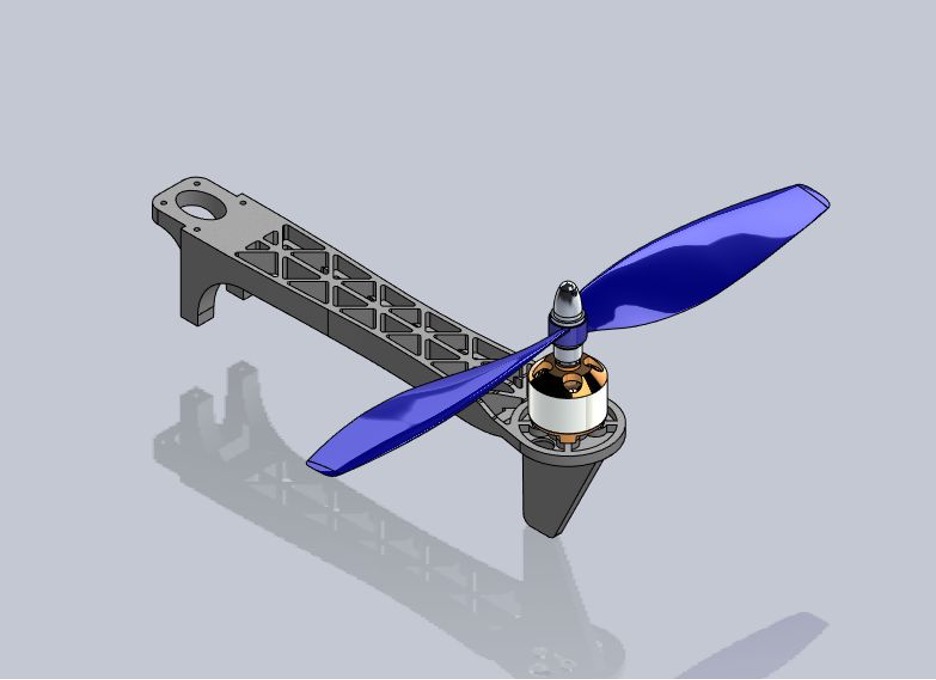

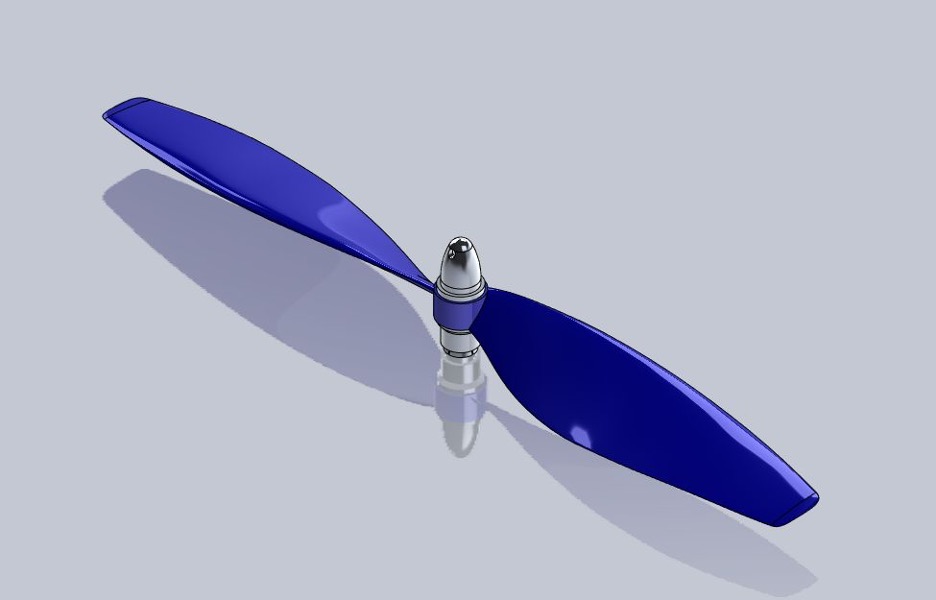

- Propeller Arm Assembly: Comprising propeller blades, motor mounts, and supporting structures.

- Propeller Assembly: Including the propeller itself, hub, and fastening screws.

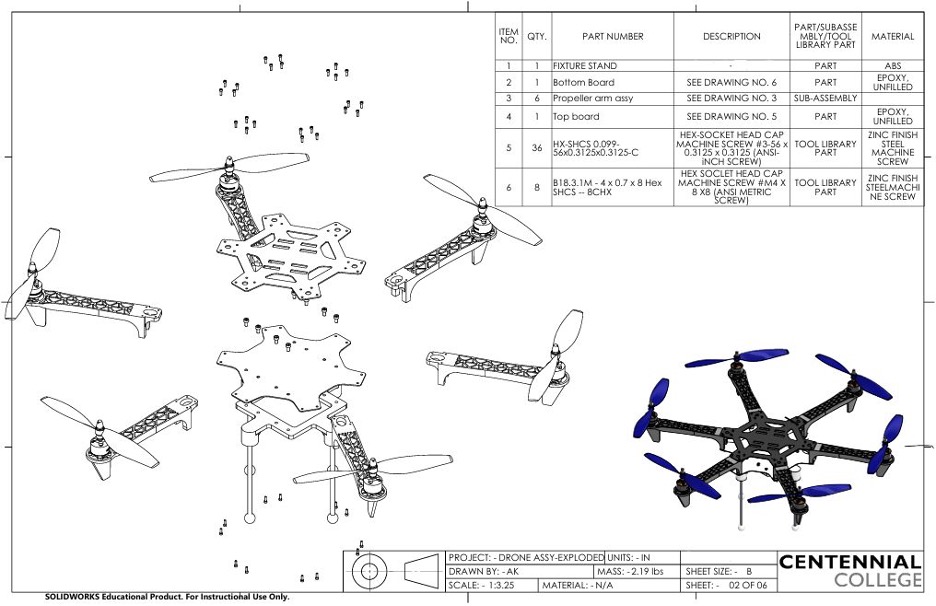

List of Components

- Fixture Stand: Acts as the support base for the entire drone.

- Bottom Board: Provides structural integrity and houses internal components.

- Top Board: Covers and protects internal circuitry.

- Propeller Arm Assembly: Sub-assembly comprising motor mount, support structure, and fasteners.

- Hex-Socket Head Cap Machine Screws:

- Size: #3-56x0.3125x0.3125 (ANSI Inch Screw). Used for critical components like motors.

- Size: M4x8 (ANSI Metric Screw). Used for minor components fastening.

Workflow

-

Individual Part Modeling: Each component was meticulously designed with exact dimensions and tolerances.

-

Sub-Assembly Creation: Smaller assemblies like the propeller and arm were created and tested for fit and function.

-

Final Assembly: All parts were integrated into a cohesive design using SolidWorks assembly constraints.

-

Documentation: A comprehensive drawing set was prepared, including views, dimensions, and BOM.