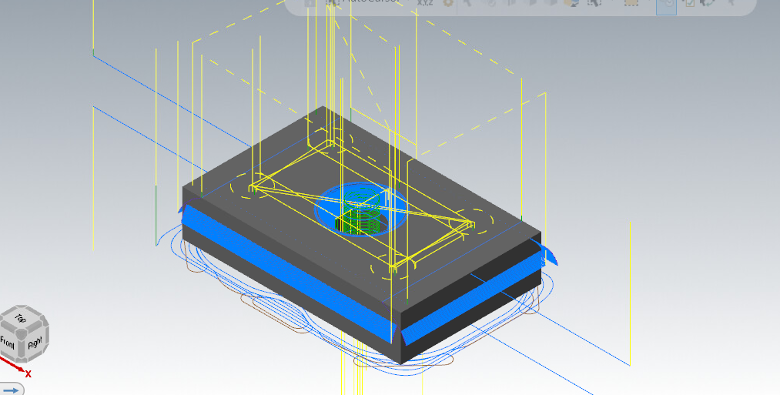

Mastercam Machining: 3 AXIS

Aafreen KaurProject Overview

This project involves the machining of a precision-engineered block, designed with multiple pockets, holes, and contoured edges for mechanical applications. The component was modeled and programmed using Mastercam, ensuring high accuracy and efficiency in manufacturing.

Machining Operations Used:

- Facing: Created a flat and smooth reference surface.

- Contour Milling: Defined the outer profile and internal features.

- Pocket Milling: Machined internal cavities with optimized toolpaths.

- Drilling & Peck Drilling: Created precise holes while preventing chip buildup.

- Boring: Enlarged and refined hole diameters for tight tolerances.

- High-Speed Machining (HSM): Improved material removal efficiency.

- Flowline Surface Finishing: Achieved high-quality surface texture by following the natural curvature of the part.

- Surface Finishing: Enhanced the final surface quality of the part.