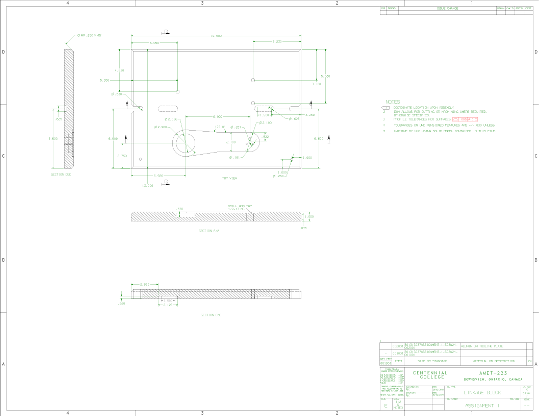

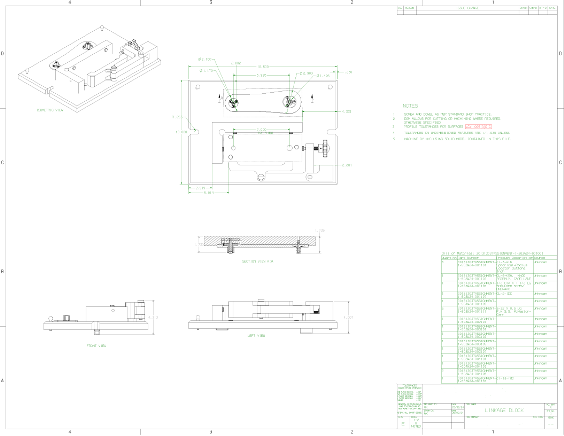

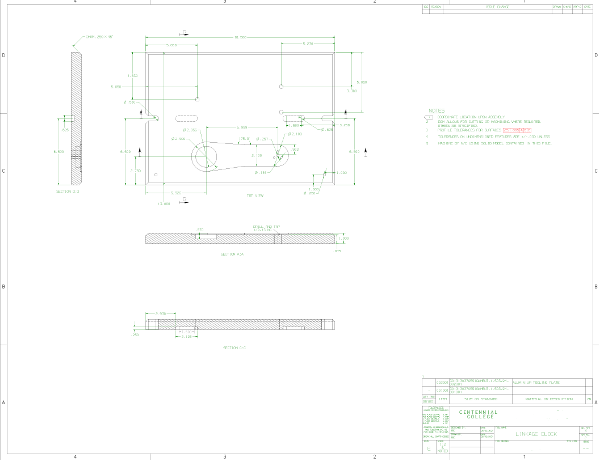

Custom Milling Fixture for Linkage Block

Aafreen KaurProject Overview

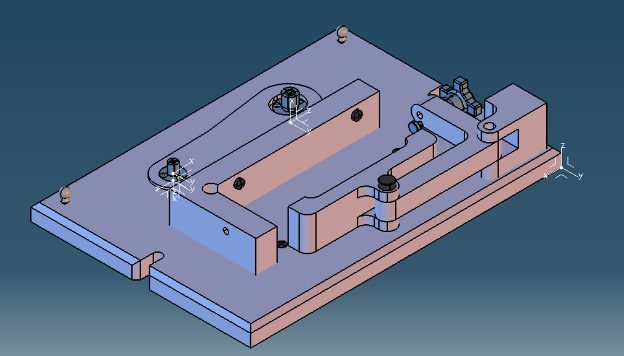

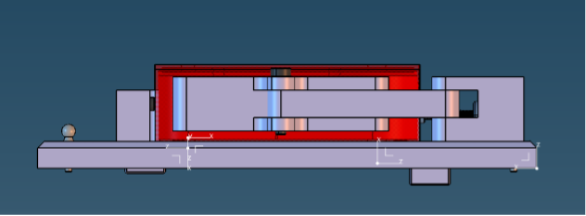

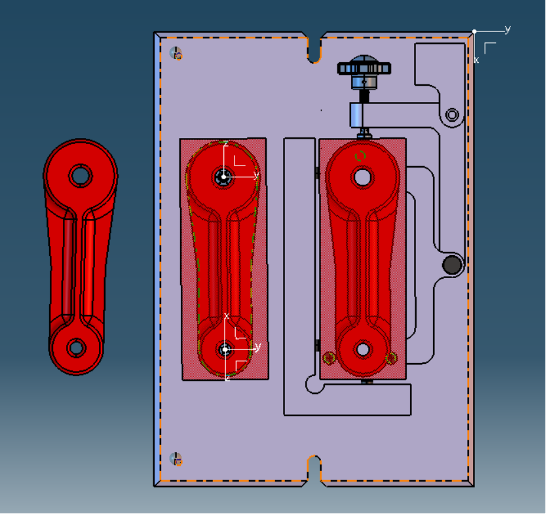

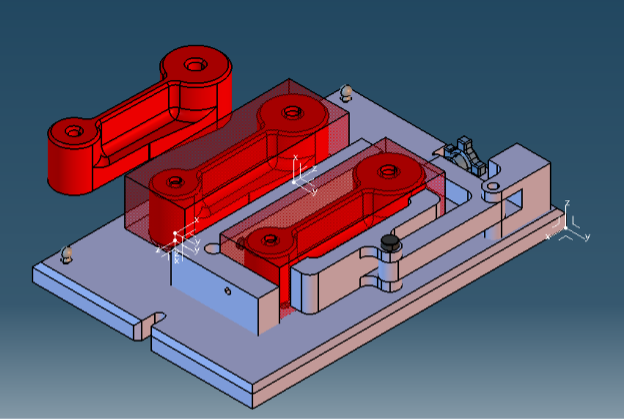

This project involves the design and manufacturing of a custom milling fixture for a linkage block, ensuring high accuracy and reliability through Geometric Dimensioning and Tolerancing (GD&T) principles. The fixture was carefully designed to secure the part during machining, reducing errors and improving consistency.

Project Details:

- Assembly and Design: Modeled and assembled each component in CATIA V5, focusing on alignment and stability. The 3-2-1 locating method was implemented to effectively secure the part, ensuring precision during machining.

- Machining Sequence: Determined based on critical features, datums, and tolerances, following GD&T principles to maintain engineering and manufacturing standards.

- Clamp Positioning Rules: Applied to ensure stability and prevent part movement during machining.

- Material Selection: Chosen based on the functionality of each tool component, optimizing durability and machinability.

- Technical Drawings: Developed a detailed set of engineering drawings, incorporating GD&T annotations to specify tolerances and datums for manufacturing.

- Bill of Materials (BOM): Created a structured BOM within the drawing, listing all required components to facilitate efficient production and assembly.