Six-Axis Industrial Robot Simulation

Aafreen KaurProject Overview

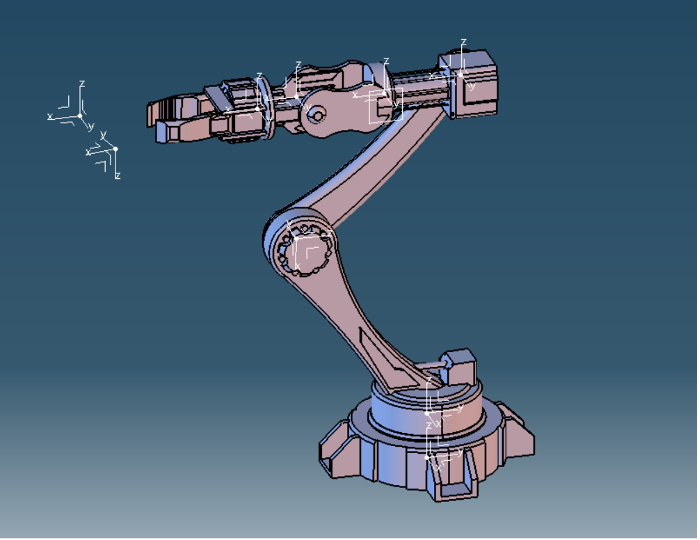

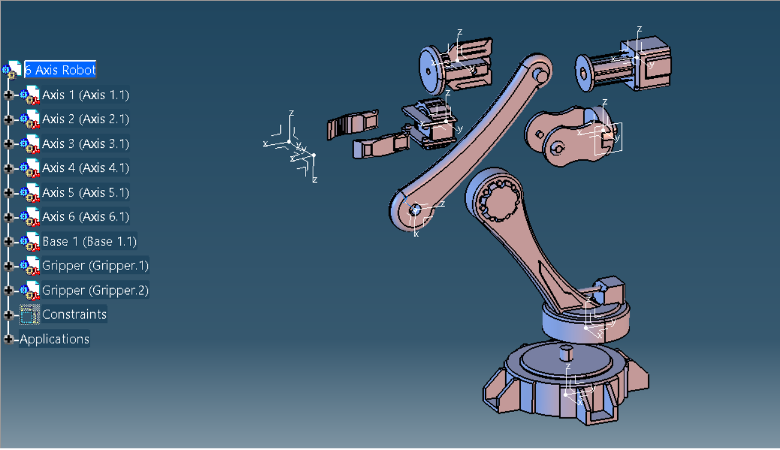

This project involves the design and simulation of a six-axis robotic arm using CATIA V5, incorporating kinematic motion to represent real-world applications. The robotic system consists of a base, a gripper, and six rotational axes. The assembly was developed to ensure precise alignment and stability, facilitating smooth motion and accurate simulation of industrial automation processes.

Motion Capabilities

The robot's motion capabilities are categorized as follows:

- Axis 1: Base rotation up to 360 degrees

- Axis 2: Forward and backward extension of the lower arm

- Axis 3: Raising and lowering of the upper arm

- Axis 4: Wrist roll, enabling rotation of the upper arm

- Axis 5: Additional movement of the arm for reach optimization

- Axis 6: Wrist rotation for precise control

Industrial Applications

The simulated robotic arm can be applied in various industrial settings, including:

- Automated assembly lines

- Material handling and logistics

- Pick and place operations